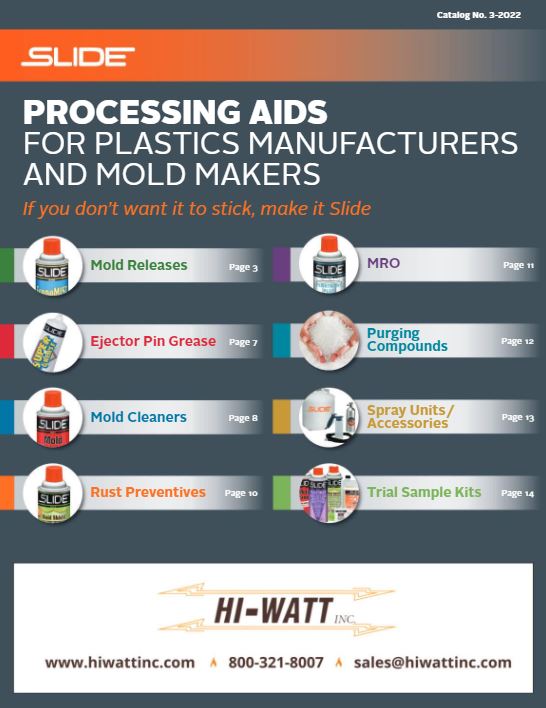

Mold Release

A release agent is a chemical used to prevent other materials from bonding to surfaces. How does it provide a solution? The right mold release agent increases production capability and extends the life of your molds. Material and application-specific formulations that prevent sticking and enable the speedy release of defect-free parts to drive greater productivity for injection or blow molding.

- Solvent-free dry formulation

- Paintable, non-silicone

- Approved for indirect food contact (†)

- Maximum operating temp: 450°F/232°CSolvent-free dry formulation

- Paintable, non-silicone

- Approved for indirect food contact (†)

- Maximum operating temp: 450°F/232°C

- Solvent-free dry formulation

- Light-duty

- Recognized by UL

- Allows molded parts to be painted or decorated post-molding

- Maximum operating temp: 650°F/343°C

- Approved for indirect food contact (†)

- No chlorinated solvents

- Paintable, non-silicone

- Mold release powder

- Use for polycarbonate, polypropylene, polysulfone and rubber molding

- Maximum operating temp: 600°F/315°C

- Approved for indirect food contact (†)

- No chlorinated solvents

- Non-paintable silicone

- Food-grade for indirect food contact – Meets 21CFR 175.300 for release agents

- Recognized by UL

- Safe to use on most resins

- Maximum operating temp: 600°F/315°CNo chlorinated solvents

Rust Prevention

It provides positive protection by displacing moisture from metal surfaces and adhering tightly to the surface. Ideal for mold and die protection, it works on stamping dies, stripper plates, jigs and fixtures, rubber mold dies, die casting dies, precision instruments, machine tools and machined or ground steel of all kinds.

- Unique “dry” formula

- Will not bleed out and mark parts

- Neutralizes fingerprint acid

- Non-silicone, non-wax formulation

- Self-cleaning in start-up

- Seals out condensation

- No chlorinated solvents

- Unique “dry” formula

- Red tracing dye helps ensure complete coverage

- Will not bleed out and mark parts

- Neutralizes fingerprint acid

- Non-silicone, non-wax formulation

- Seals out condensation

- Bulk versions of this product should be thoroughly stirred prior to use

- No chlorinated solvents

- Displaces moisture while sealing mold from outside condensation

- Non-silicone, non-wax formulation

- Neutralizes fingerprint acids

- No chlorinated solvents

- Protects molds when using PVC and flame-retardant resins

- Provides dual protection against moisture and hydrochloric acids

- One-step rust preventive

Mold Cleaner

Mold cleaners are designed for removing tough resin deposits, silicone and other contaminants, with some formulations customized for the temperature at which they are used and by the products being molded. Mold cleaners for injection and extrusion operations have a critical job to do in dissolving and removing resins, grease, oil and other contaminants that can leave molded parts damaged and affect the life of a mold.

- No chlorinated solvents

- NSF category P1

- Evaporates fast; leaves no residue

- Convenient method for removal of mold release, grease, oil and wax build-up on mold surfaces

- Slide’s most popular mold cleaner formulation

- No chlorinated solvents

- NSF category P1

- Offers more cleaning strength than other “natural” mold cleaners

- Can be used to help break down resin deposits from the mold surface and clogged vents

- No chlorinated solvents

- Food-grade for indirect food contact (21CFR 178.3530)

- Very low odor

- Quickly removes mold release, grease, oil and wax build-up on mold

- No chlorinated solvents

- Pre-saturated cleaning towels

- Quickly removes mold release, grease or oil from mold surfaces

- Mold cleaning option for clean room environments

Purging Compounds

Slide’s purging compounds speed up resin-to-resin and color-to-color changes, maximizing your productivity and decreasing the costs.

- Excellent purge for use through hot runner systems

- Safe to purge through the mold

- Helps eliminate color streaking and black specs

- Effectively removes old resin and color residue in extrusion, injection and blow molding operations

- Low odor

- GRAS rated (food-grade) active ingredients safe for food packaging applications

- Excellent for use through hot runner systems

- Safe to purge through the mold

- Helps eliminate color streaking and black specs

- Chemically reactive compound

- Polyolefin resin carrier

- Operating temperatures of 330° – 610°F/165°C – 321°C

- For use with injection molding, extrusion and blow molding

- GRAS rated (food-grade) active ingredients safe for food packaging applications

- Complete purging through reactive chemistry

- No need for multiple purging products

- Temp range: 160° – 600°F/71°C – 315°C

- Ready to use; no mixing required

- Run through gates as small as 30 microns

- FDA compliant – ingredients meet G.R.A.S. standards

- Aids with resin-to-resin and color-to-color purges

- Not for use with acetal or Delrin®

Slide Rust Prevention

Slide Purging Procedures

Slide Pin Lubrication

Slide Freedom Spray Unit

Slide Cleaning Molds Metal

Slide Applying Mold Release

Speak with an expert

Over last 8 years we have addressed 95% of inside sales quoting requests within 3 hours.