Single-Loop PID Temperature Controller

A single-loop process controller is a scalable, affordable option. These precision devices measure the status of a system variable and initiate an alarm when values go outside of your programmed tolerance.

Our controllers come with industry-standard connectivity protocols so you can integrate into future or existing logging and reporting processes. We also offer a variety of panel-mount packages for stability and integration into your plant or lab environment, including Watlow PM Legacy.

Single-loop controllers are the base element of a more affordable, more reliable industrial, commercial or scientific process. They are simple to use, easy to integrate into existing equipment and require minimal space.

Multi-Loop PID Temperature Controller

Multi-loop temperature and power controllers provide the flexibility, simplicity of management and advanced oversight necessary for highly specific applications. We carry options from leading manufacturers such as Gefran and Watlow.

Multi-loop control systems are highly scalable and flexible due to the ability to combine various modules. Some high-density type can control up to 152 loops with up to 256 monitor points. Robust reporting and communications integration give you the data you need to analyze, control and improve your processes.

Power Controls

Power controls are an essential component of any PID temperature controller system. These switching devices help provide a variety of benefits:

- Better system performance

- Full service life for other devices

- Increased safety

- Power oversight through communications ports

Our PID temperature power control options come from industry leaders, such as Watlow and Gefran. They carry industrial-level certifications from CE and UL. The exact configuration we recommend would depend on your use case, but options include:

- Integrated fuses and heat sinks

- Serial ports

- Short circuit ratings up to 20,000 A

- 18-1,000 A operation ratings

- Various fire options

- Various phase and leg options

Temperature Limit Controller

Limit controllers provide safety beyond what a PID temperature controller can provide. Beyond even the alarm capabilities of standard controllers, these provide a backup shut-off option for systems at risk of reaching critical temperature levels.

The common application of temperature limit controllers is to add safety to the control loop for RTDs, thermal switches and thermocouples. These devices augment the function of:

- Sensors

- Main temperature controllers

- Heater control relays

We carry the PM Watlow limit controller series and several other leading options. Our clients trust these micro-controller-powered units for productivity, safety and risk reduction. All options have UL or FM compliance certification.

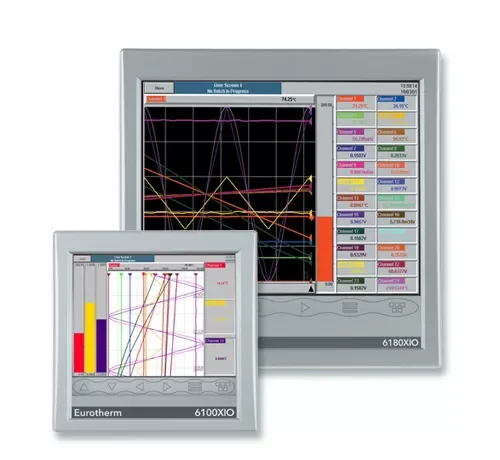

Data Logging and Recording

Even simple PID temperature controller implementations are improved by enhanced oversight. Our data logging and recording solutions provide the actionable information our clients need to stand out in their industries:

- Historical data to track performance trends

- Up-to-date conditions of remote processes

- Easy-to-understand interfaces and outputs

Our preferred product is the Watlow F4T. It is a touchscreen, flush- or panel-mount device with robust upgrade options through up to six flex modules, high-speed USB ports for data transfer support, ethernet connectivity. It is completely programmable and customizable. Other features include:

- I/O expandable from 1 to 36

- 0-2 cascade, 1-4 PID control loops

- 40 ramp-and-soak profiles with 50 steps each

- AC current, universal and thermistor measurement inputs

SpecView Software

Watlow SpecView HMI software is behind the successful implementation of many PID temperature controller systems. It is a supervisory control and data acquisition suite compatible a wide range of hardware, including:

- Watlow’s F4 series of controllers

- Watlow EZ-ZONE controllers

- ASPYRE temperature controllers from Watlow

- Watlow PM Legacy™ and PM Plus™

- Many types of third-party equipment

SpecView is a cross-industry solution. We have clients in aerospace, injection mold tooling, defense, chemical processing and more who use this software. This SCADA software offers a host of benefits above and beyond competitors:

- Built-in support for Watlow controllers

- Cost-effective

- Robust logging and reporting

- Automation and customization options

- Intuitive human-machine interface design

- Easy-to-use integration of multiple controller types