SpecView HMI software from Watlow® is a cost-effective, easy-to-use Human Machine Interface software for Watlow controllers, including EZ-ZONE® integrated temperature controllers and various third-party products. Watlow’s single point of support for hardware, software and application needs ensures knowledgeable and expedient response to all of your questions or concerns.

This HMI software for temperature controllers is commercially accepted and price competitive compared to third-party options. Throughout its history, field-proven features and functions have been added based on customer suggestions.

What Is SpecView?

Discover the benefits of intuitive controllers for your Watlow products with Watlow software. If you’re looking for a streamlined HMI, or human machine interface, for your Watlow heaters and industrial controllers, learn more about this easy to use software today. Find all the answers to your essential questions and find out how Hi-Watt can assist you in implementing this state-of-the-art HMI in your facility.

SpecView allows you to easily operate a range of power controllers for diverse industrial applications. A wide range of industries and controllers types successfully use this Supervisory Control and Data Acquisition (SCADA) software. Here are a few patented Watlow controllers that are compatible with this particular software:

- EZ-ZONE controllers

- ASPYRE power controllers

- F4T with INTUITION process controllers

- Third-party controllers and other products

A major factor in choosing SpecView is the integrated nature of this software. Because Watlow produces the software and hardware for your industrial controllers, this software automatically communicates efficiently with your controller, which reduces installation and programming time.

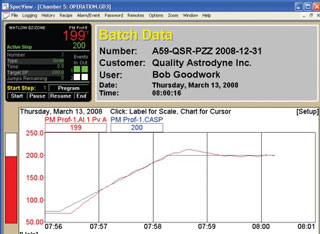

Bar code reading, process adjusting, machine troubleshooting and data logging are just a few of the popular capabilities of this easy to use software from Watlow. Depending on your industrial need, you can easily adjust the screens, data logging and other features to fit your particular equipment and operation.

Benefits of SpecView

Create efficient operations and data logging capabilities with your Watlow controller and it’s compatible software. After installing it in your Watlow controller, you’ll discover these and other benefits:

- Convenient customizable screens

- Customizable data logging

- Detailed report generator

- Auto-detect support

- Comprehensive task automation

- Built-in Watlow controller support

Use the integrated report generation capabilities to create AMS 2750D NADCAP compliant reports. These detailed reports not only assist you in increasing efficiencies throughout your facility, but they also ensure your operations comply with the latest regulations and other requirements.

Whether you’re using a Watlow controller or a compatible third-party option, the aforementioned software is easy to install and integrate with your current control system. Use the flexible screen controls to recreate your current control system or create an even more efficient setup.

As a leader in industrial controller software and hardware, you can expect Watlow to stay at the forefront of the industry. Expect the latest features and intuitive controls for all your Watlow controller operations. From recording operator actions to automating chosen parameters of data collection, few software options can compete with the cutting-edge features of SpecView.

Compatible Products

There is a range of controllers that are compatible with this Watlow software, so discuss your controller option with Hi-Watt today to determine whether SpecView can operate efficiently in your facility. Here are some common controllers that easily integrate this competitive software option:

- EZ-ZONE PM and PM Express Controllers

- F4D Ramping Temperature Controller

- F4S Ramping Temperature Controller

- EZ-Zone RM High-Density Control Module Controllers

- EZ-Zone RM Control Module Multi-Function Controller

Your injection mold tooling, chemical processing or defense and aerospace facility needs the latest in controller software. Watlow produces leading controllers and heating technology for these and other industries, so consider whether you need to update your current Watlow controller or replace a third-party option with a leading brand of industrial controller.

Whether you need to control operations, log data or monitor temperature settings, know that this is a competitive option for your industrial application. Many third-party controllers can operate this software, so you may not have to change out your controller to enjoy the latest in HMI technology.

Learn More Today

At Hi-Watt, we offer industry-leading technical support for all your industrial heater and controller needs. Whether you need expert assistance in operating this HMI software or you’re considering replacing your entire Watlow controller and installing it for the first time, contact us today. We meet over 97% of our customers’ deadlines, so we’ll work with you to update your controller software with minimal downtime and comprehensive support.

Built in Support

This software’s built-in support and auto-detect for Watlow controllers has various advantages compared to tag-based systems. Since there is no steep learning curve or additional need to learn intricate details having to do with communication protocols to configure software, setup is quick and simple.

Process adjustments and machine troubleshooting are simply and easily accomplished by using graphed data on trend charts. SpecView from Watlow is designed for industrial needs, and it includes built-in compatibility with bar code readers and touch screens.

Flexible Features

Customizing displays for specific applications reduces process errors. Flexible features include data logging, a historical replay option, easy-to-use recipes and remote access options. To try before purchase, download tghis software from Watlow from the Literature & Downloads tab below and run it in the time-limited demo mode.

Specifications

| Description | Human machine interface for Watlow controllers |

| Supported Controllers: | EZ-ZONE PM, RM, ST, SERIES F4 Ramping, SERIES 96, 97, SD, POWER SERIES, MICRODIN, CLS200, MLS300 |

| Operating Requirements: | Windows® 8, 7, Vista, Server 2003, XP (Home and Professional), 2000, NT 4.0, ME, 98 and 95 |

Speak with an expert

Over last 8 years we have addressed 95% of inside sales quoting requests within 3 hours.