Benefits of Using RTDs

These industrial temperature sensors are good measuring tools for extremely hot and cold materials. Their limits vary depending on the resistance element’s metal. For example, platinum’s melting point is 1,768 degrees Celsius and nickels is 1,455 degrees Celsius, so RTD temperature sensors with platinum resistance elements are better equipped for high temperatures than nickel ones.

Another benefit of RTDs is that they deliver accurate temperatures quickly. Most RTDs calculate their temperatures within 0.5 and 5 seconds, and it is easy to run the conversion process again if you’re not satisfied with the results. Our customers also appreciate the way that RTD temperature sensors stay functional for a long time, even when they’re exposed to high temperatures.

Common Types of Resistance Temperature Detectors

Resistance temperature detector sensors’ types vary based on their wire material and construction. Copper, nickel, and platinum are the most common choices for RTD wires because they exhibit the required relationship between temperature and resistance.

Copper resistance temperature detectors can measure between -200 and 260 degrees Celsius, making them the best for cold environments. These RTDs tend to be cheapest because copper is inexpensive, but they run the risk of oxidizing if our clients do not watch their temperatures’ upper limits.

Nickel sensors are inexpensive and better at resisting corrosion than copper ones, but they can only measure between -80 and 260 degrees Celsius. Platinum RTDs are more popular because of their versatility. Capable of measuring temperatures between -200 and 850 degrees Celsius, these RTDs last for a long time and give stable, consistent results.

We also classify our RTDs based on their construction. Thin-film RTDs have the smallest, cheapest, and fastest design, and they are usually made of platinum film spread across a ceramic foundation. Coiled element RTDs involves coiling the resistance element into wires and containing them in a protective ceramic container.

Finally, wire-wound RTDs, which are highly accurate but too breakable for manufacturing applications, feature wires coiled around a ceramic column and coated in more ceramics.

How To Choose an RTD

To choose an RTD, consider whether you want a platinum, nickel, or copper resistance element, keeping in mind their temperature limits. You should also weigh their standard tolerances or the relationship between the material’s temperature and the metal’s resistance.

Accuracy and acceptable margins of error, which vary based on your industry, are also big concerns. Finally, think about the sensor connections: the lead wires’ material, the number of leads present, and their configuration.

For your rapid and accurate temperature-sensing needs, check out our selection of resistance temperature detectors.

RTD Accessories:

We distribute the best RTD temperature sensors for excellence in laboratory and industry processes. Most RTDs have a low initial resistance, commonly 100 ohms.

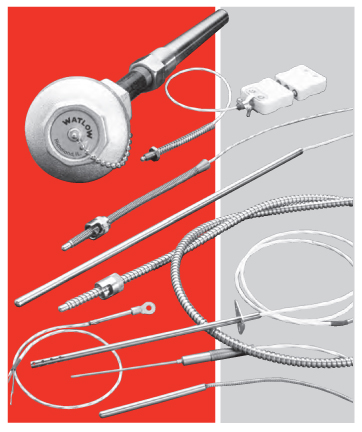

They also have a minimal resistance change per unit of the temperature range. Because of this, a multiple wire bridge is built into the RTD to compensate for the lead wire resistance. Our standard and heavy-duty resistance temperature sensing products include the following:

- Tube and wire

- Metal transition with spring strain relief

- Standard and mini plug

- Connection head

We also supply reliable RTD sensor accessories including standard and mini connectors, extension wire, and connection heads.

Watlow Resistance Temperature Sensors

Watlow manufactures a variety of RTDs that are specially designed to ensure precise and repeatable temperature measurement. Watlow RTD sensors are built to meet the most demanding industrial applications while providing a lower total cost of ownership for our customers.

Strain-free construction provides dependable, accurate readings and allows elements from different lots to be substituted with no recalibration needed.

Common Applications of RTDs

Typical applications include: Stoves, grills, fryers, and other food equipment, Textile production, Plastics processing, Petrochemical processing, Air, gas, and liquid temperature measurement, Semiconductor processing as well as Bearing and gearboxes.

Thermistor Sensor for Rapid Detection

Temperature changes are detected rapidly with a thermistor sensor that delivers accuracy. The sensitive thermistor is comparable to an RTD because its resistors reflect resistance changes. The economical thermistor contains coated metal oxide materials.

This sensing instrument is often preferred when a smaller temperature range is acceptable. Contact our experts to choose the right thermistor temperature sensor for your thermal applications.

Compare RTD Sensors Industrial temperature sensors at Hi-Watt with other common temperature probes, such as thermocouples and thermistors, to discover the ideal option for your industrial application. Learn more about an RTD, or resistance temperature detector, and how it can offer you the resistance and lifespan you need to keep your facility going. Don’t let a faulty sensor or improper replacement probe prevent you from keeping your processing facility functioning.

Thermistors vs. Thermocouples

A thermistor is used in many of the same applications as an RTD but includes either a polymer or ceramic resistor instead of a typical metal resistor. When you compare thermistor vs thermocouple, you’ll find a thermistor is ideal for finding minute changes in temperature but doesn’t have the same temperature range capability of a thermocouple, which can handle a temperature range up to -200 to 350 degrees Celsius.

Thermocouples vs. RTD Sensors

Compare an RTD vs thermocouple to discover the power of an RTD in the right application. Compared to a thermocouple, an RTD has a relatively small temperature range, though not as small as a thermistor. An RTD offers linearity and the highest levels of temperature measurement accuracy, while a thermocouple is best suited for wide, non-linear temperature readings.

The sensor you need depends on your application. While all three of these temperature probes are used to measure changes in heat, none compare with RTD sensors in terms of accuracy. Thermocouple sensors, on the other hand, have by far the widest range of operating temperatures.

Find Your Industrial Temperature Sensor Today

At Hi-Watt, we offer all the temperature sensor options you need for most industries. Whether you’re operating a plastic processing, injection mold tooling or aerospace facility, contact us today to learn more about these sensor options. Speak to one of our tech support agents today and work with us to schedule a shipment of leading sensors to keep your company moving forward.

Speak with an expert

Over last 8 years we have addressed 95% of inside sales quoting requests within 3 hours.