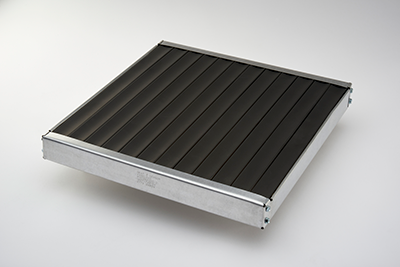

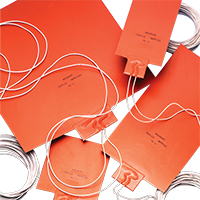

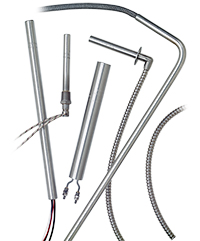

As a leading distributor of industrial electric heaters, we understand the critical connection between high-quality equipment and on-time operations. Hi-Watt electrical heaters for industrial processes perform dependably in the most demanding applications. These products are engineered – with a commitment to superior design – by top manufacturers, such as BriskHeat, Chromalox, Marathon Heater, Tempco, Watlow and more.

You’ll have access the following types of commercial and industrial process heaters with Hi-Watt: