Linear Transducers for Plastic Molding

A linear transducer, or linear potentiometer, measures movement or linear displacement along a single axis, then converts that information into an electrical signal. The signal level is proportional to the displacement of the product or machine’s position. The conversion of electrical signals into real-world data is the basis of automated process control, which makes it possible to know the position, level, pressure, flow, or presence of variables in a process.

Linear transducers are crucial in today’s automated manufacturing processes, as the process data collected from them is fed into programmable controllers that make decisions at every production stage.

Linear transducers are typically installed in plastic injection presses and vertical presses, for barrel and tool positioning. Hi-Watt offers GEFRAN linear potentiometers for their quality and reliability.

Types

There are multiple types of contact and non-contact linear transducers, which differ by form factor and the sensing technology used to measure the position and/or speed of a part.

These two primary types can be further split into several categories: Linear variable differential transformer (LVDT), fixed, rodless, and spring-loaded.

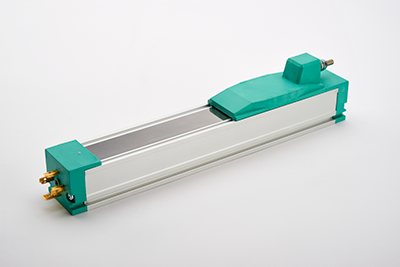

Rodless

A rodless linear transducer sensor can be contact or non-contact. It features a wiper that moves along the entire sensor length in place of a projecting rod, and its resistive element provides position feedback to the process control system. These sensors are cost-effective, require very little space, and are available with magnetoresistive technology. Rodless transducers can be commonly found in many applications, including material handling systems, packaging and labeling machines, aircraft co

LVDT (Linear Variable Differential Transformer)

An LVDT linear position sensor is a virtually frictionless, non-contact sensor that uses electromagnetic coupling to convert a linear or positional displacement into an electrical phase signal for direction and amplitude for distance information. LVDTs are AC-operated as opposed to using low-voltage electronics and are commonly used in cryogenic applications and harsh environments with extreme vibration and shock levels.

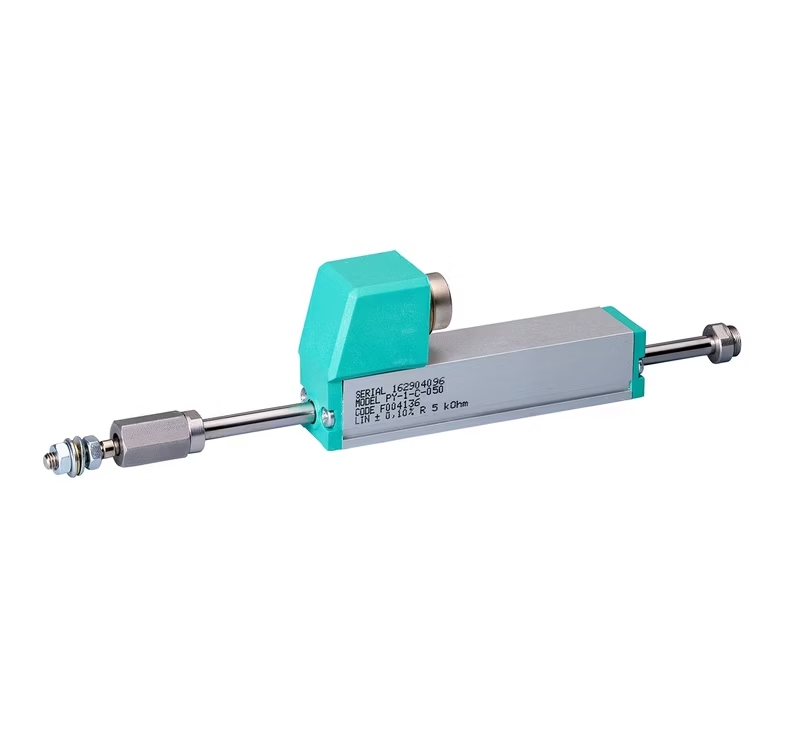

Fixed

A fixed slide linear position sensor is a non-contact transducer designed for easy installation. It features a rectangular or cylindrical housing mounted in a fixed position and a shaft connected to the moving or traveling object. These devices are designed for fast-paced assembly and factory automation applications that require a superior stroke-to-body length.

Spring-Loaded

The spring-loaded linear transducer is a type of contact sensor that features a slide actuator pushed into the body of the sensor. It features a ball tip to measure the distance traveled when first pressed. These units are preferred for applications where the sensing element must be detached from the object whose position is being measured. They are available in magnetoresistive and inductive technologies.

Plastic Manufacturing Applications

Linear transducer sensors are used in the plastics industry because most types offer a non-contact, heavy-duty, and accurate way to mark machine positions. They are also durable and wear-free, which keeps automation maintenance costs low.

Some common applications for linear transducers in the plastics industry include injection molding and blow molding.

Injection Molding

Plastic injection molding machinery typically requires tracking four or more linear positions to control the process. Manufacturers rely on linear position sensors because they are designed to be reliable and accurate for large production volumes that require good repeatability.

Magnetoresistive linear sensors (like rodless and spring-loaded) are typically used on injection molding equipment because they can withstand the high temperatures, shock, and vibrations common with injection molding.

Blow Molding

Linear position sensors are also used in the blow molding process. They’re known for their excellent linearity, long mechanical life cycle, and ability to withstand rugged environments. Additionally, with linear sensors, it’s possible to program positioning of up to 0.005 millimeters to meet the length or thickness requirements of blown film production.

Do You Have Questions About Linear Transducers? Contact Hi-Watt Today!

Founded in 1979, Hi-Watt is a trusted resource and supplier of linear transducers by manufacturers like GEFRAN.

Contact us today if you have general questions about linear transducers or need help selecting the best one for your application.