Improving F4T Performance With Watlow’s COMPOSER® Software

Watlow’s F4T controller with COMPOSER® is revolutionizing the configuration and control of heat management systems. It’s designed to simplify arduous tasks, such as managing inputs and outputs and setting up control loops and alarms.

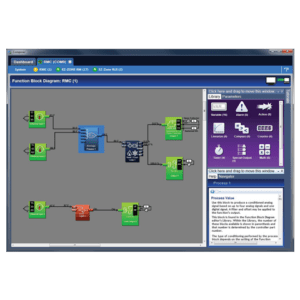

But it doesn’t stop there! The genius lies in its intuitive design, allowing users to quickly pick up on configuration options through a function block diagram.

In the sections below, we will dive deeper into how your organization can improve F4T controller performance with Watlow’s COMPOSER® software. Let’s jump in!

Benefits of COMPOSER®

The COMPOSER® software package completely revolutionizes how you interact with your heating systems, offering you a unique blend of convenience and control.

Some of the benefits of using COMPOSER® with your Watlow F4T controllers includes:

- Easy to Use & Troubleshoot: COMPOSER® allows you to configure controllers according to specific applications and provides a visual representation of your configuration, making it simple to understand and illustrate to others. It also improves application testing and troubleshooting capabilities.

- Multi-Language Capabilities: The multi-language capability eliminates confusion and reduces potential errors.

- Convenient for Remote Users: COMPOSER® supports remote users by making it easy to duplicate settings and sending configurations, as well as providing backups in case changes are made or the controller is replaced.

- Simple Dashboard View: With dashboard view, the software flags configuration errors that require attention and allows configuration files to be downloaded without accessing setup and configuration views.

- Intuitive Profile Editor: The user-friendly profile editor speeds up the process of creating and editing profiles. It also facilitates the management of profile lists in controllers from a remote PC and makes backups and transferring profiles from one controller to another a breeze.

- Robust Ethernet Support: COMPOSER® allows easy connection to one or more controllers, reducing the time required to read and write configuration settings.

- Pluggable Flex Module Management: This software simplifies configuration by clearly indicating existing hardware. It also streamlines the commissioning processing, allowing users to set up the controller for flex modules before installation, thus saving time.

- Flexible Permission Settings: COMPOSER® allows managers to restrict access to particular features. Restricting access helps to prevent mistakes and minimize downtime by protecting against unintended configuration alterations.

- Faster & Simplified Calibration & Verification Process: The controller, when paired with COMPOSER®, drastically reduces the calibration/verification procedure for technicians.

Applications

The Watlow F4T controller backed by COMPOSER® software is the ultimate solution for a wide range of applications, including:

- Process & Machine Control: The F4T controller integrates seamlessly with many devices, significantly reducing complexity while saving time and money. It incorporates the functionality of multiple devices into one system and gives the option of PID loops, cascades, humidity control, and compressor control.

- Power Management: Watlow’s new F4T software can easily regulate power input and output. It simplifies profile creation and editing and facilitates optimal power control.

- Temperature Monitoring & Control: With features like thermocouple temperature sensing, current sensing, and infrared temperature sensing available at your disposal, Watlow’s F4T controller with COMPOSER® strengthens temperature monitoring like never before by allowing you to keep track of various thermal parameters from a distance.

- Hydration & Moisture Control: F4T with COMPOSER® allows the management of humidity sensors and control loops. This becomes particularly handy in managing processes where moisture can play a significant role.

- Automation: The F4T changes the game entirely for those looking to automate their processes. It has adaptive control, a 4 PID loop maximum for advanced process regulation, and a convenient touchscreen interface that helps reduce potential errors.

System Requirements

- Compatible Operating Systems: The software runs smoothly on Windows® 10, Windows® 8.1, and Windows® 7.

- Microprocessor: Your system should have a microprocessor that is 1 gigahertz (GHz) or faster and can be either 32-bit or 64-bit.

- Memory: You’ll need a minimum of 1 gigabyte (GB) of RAM for a 32-bit system or 2 GB of RAM for a 64-bit system.

- Disk Space: You must have at least 250 megabytes (MB) of disk space available for the software.

- Video Resolution: Your video resolution should be 1280 x 720 or higher for optimal interface display.

- Port Requirements: If you’re using the F4T controller, you’ll need an Ethernet port for communication.

How to Program This Software

Mastering Watlow’s COMPOSER® software is essential if you want to optimize the performance of your F4T controller. Although there are several programming steps, the software is intuitive and easy to navigate overall.

The first step is installing the software— you’ll want to ensure that your PC meets software system requirements.

After you successfully install the software, you must connect your PC to the F4T controller. Once you do, the software will guide you through the dashboard. Once familiar with the dashboard. You can easily configure Flex Modules (FM), which are key components of the F4T system.

Then, you’ll use the function block diagram to configure your application. The function block diagram allows UI personalization and provides a clear view of controller configuration through representative blocks. When the initial setup is complete, you’ll establish data log files, which are vital for process documentation and future troubleshooting.

The creation and editing of user profiles come next. The software’s profile editor facilitates this process, allowing for both individual and multiple user setups. Once you create profiles, you’ll want to familiarize yourself with the F4T menu, which is the central hub that gives you access to all controller functions, as well as select your language preference in the global settings and configure Ethernet to the controller.

Download the F4T setup operation manual today to access a comprehensive step-by-step guide.

Explore the Benefits of Watlow’s F4T Controller With COMPOSER®

Located in Michigan, Hi-Watt is a trusted regional distributor of industrial heating solutions, including temperature sensors and process controllers, from trusted brands like Watlow.

Please contact us today if you have questions about Watlow’s F4T controller with COMPOSER® or to request a quote.