Hi-Watt is proud to be Michigan’s leading distributor of Watlow industrial heating solutions. We chose to partner with Watlow because they offer world-class technology that can’t be found anywhere else. They have over a century of experience engineering products that help overcome common challenges in numerous industries, ranging from aerospace to plastics and chemical processing.

You can turn to Watlow for reliable solutions for any application—we can even engineer custom solutions based on your needs. Check out our range of Watlow heaters, sensors, controllers, and other thermal solutions below, or contact us today to speak with one of our application specialists.

Popular Watlow Products We Carry

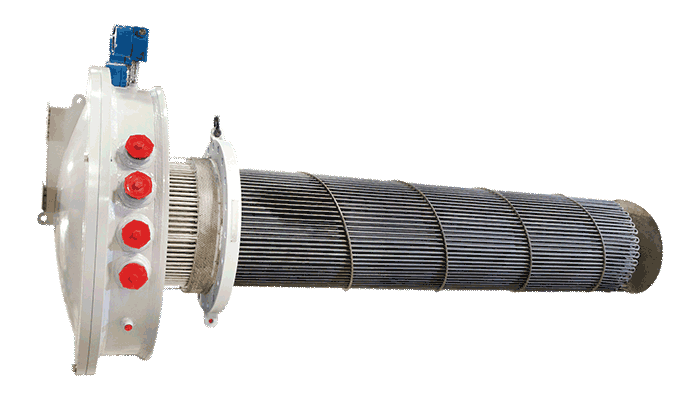

Industrial Heaters

Hi-Watt carries a wide selection of Watlow industrial heaters, including immersion, circulation, cartridge, and whole temperature control systems.

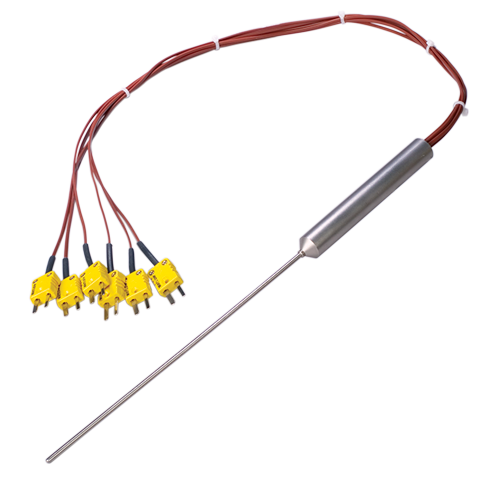

Industrial Temperature Sensors

Get real-time feedback on your control systems with Watlow’s line of RTD sensors and thermocouples. All temperature sensors can be uniquely configured based on your application requirements.

Temperature Process Controllers & Data Recorders

We carry all Watlow single-loop and multi-loop process controllers in various form factors, including 1/32 DIN panel mount, 1/16 DIN panel mount, 1/8 DIN panel mount, 1/4 DIN panel mount, and DIN rail mount for continuous data management and process control, as well as data recorders for simple data monitoring applications.

Temperature Power Controllers

With Watlow’s line of power controllers, you can eliminate temperature overshoot, improve response times, and reduce thermal stress. Hi-Watt carries all available series, including ASPYRE® and DIN-A-MITE®.

Customization Abilities

In addition to selling Watlow’s entire suite of thermal processing products, Hi-Watt’s application specialists can help you configure a custom solution based on your unique requirements. We carry heaters and thermocouples in various diameters and lengths, lead types, and more. Start customizing your solution today by visiting our configurator page.

Resources

Talk to a Hi-Watt Application Specialist Today

At Hi-Watt, we understand that every business is different. That’s why we work hard to deliver custom-tailored solutions that help companies like yours improve operational efficiency, maintain safety, and ensure precision. Contact a Hi-Watt application specialist today to find your solution, and we’ll show you why we’re Michigan’s leading distributor.